Rapid Prototyping - Text

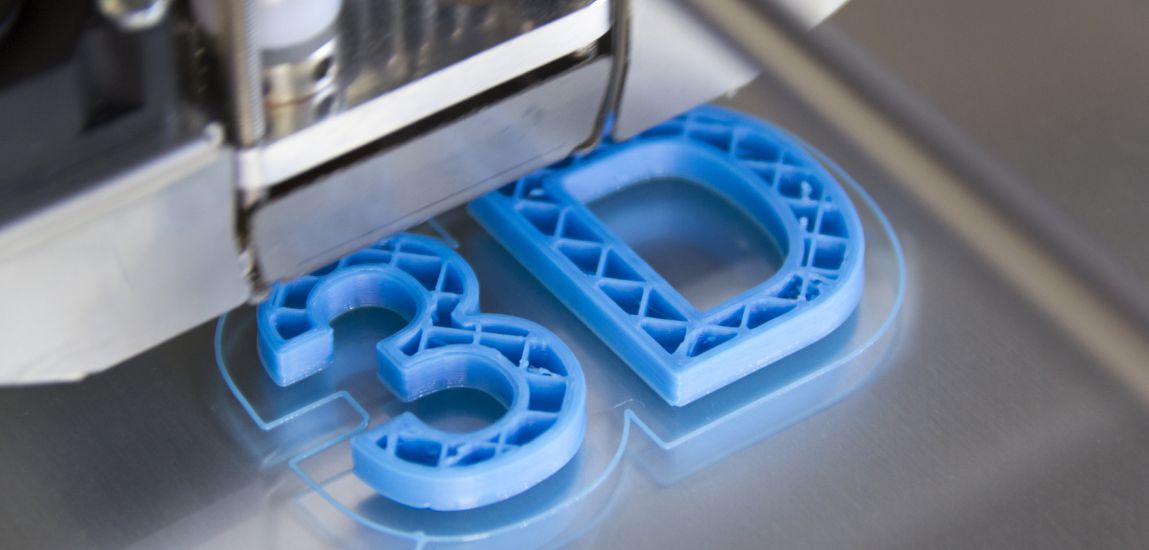

3D printing is an additive manufacturing process. In contrast to machining, nothing is taken away, but added! A rework of 3D printed parts is usually not necessary, apart from the finest adaptations. There are no chips and no waste. With 3D printing, it is possible to produce infinitely complicated parts. Disadvantages of 3D printing are a relatively long printing time and a mostly bad surface of the parts. In comparison, a smaller plastic part can be made by injection moulding in less than a minute. The injection-moulded part also has a higher strength and a better surface. An injection moulding tool for the smaller plastic part, however, costs many thousands of euros, must first be designed and manufactured expensively.

Despite the long printing time, 3D printing is also called rapid prototyping because it was originally used only for the rapid production of prototypes. These were mostly used exclusively for presentation or study.

Aerospace, on the other hand, already uses series parts from the 3D printer. 3D printing makes it possible to produce infinitely complex parts. For example, workpieces with a honeycomb structure inside and a thin outer skin can be produced. This results in an extremely lightweight and quite stable construction.

upper picture: FDM-3D printer (linked from www.allesdrucker.de)

lower picture: 3D-printed glasses frame (linked from www.blogspot.com)